Victorinox Rescue Tool

09.09.2024

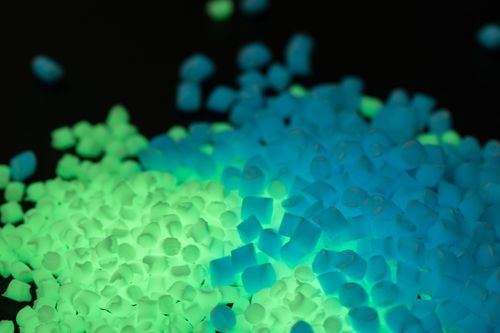

The indispensable emergency tool for smashing windows and cutting seat belts. With luminescent shell handle.

STORELITE® offers photoluminescent solutions for emergency services, unique designs or safety markings. We would be happy to develop a customised product for your application.

Victorinox Rescue Tool

09.09.2024

The indispensable emergency tool for smashing windows and cutting seat belts. With luminescent shell handle.

PVC flooring colorex signal from forbo

09.09.2024

With Colorex Signal Glow EC, emergency exits and escape routes can be marked.

DAY & NIGHT soother from Medela

09.09.2024

The knob of the soother glows softly in the dark so that the soother is easier to find.

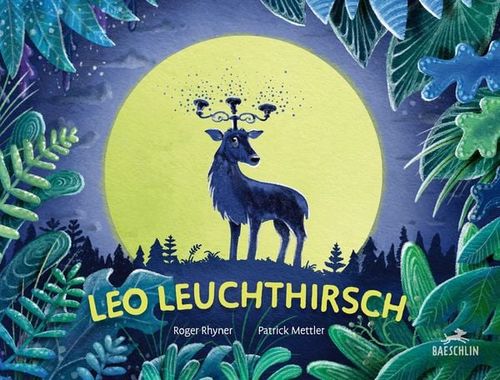

Children's book Leo Leuchthirsch

09.09.2024

The children's book by Roger Rhyner with illustrations by Patrick Mettler was given a luminous cover thanks to our STORELITE® pigments, which replaces the night light in children's rooms.